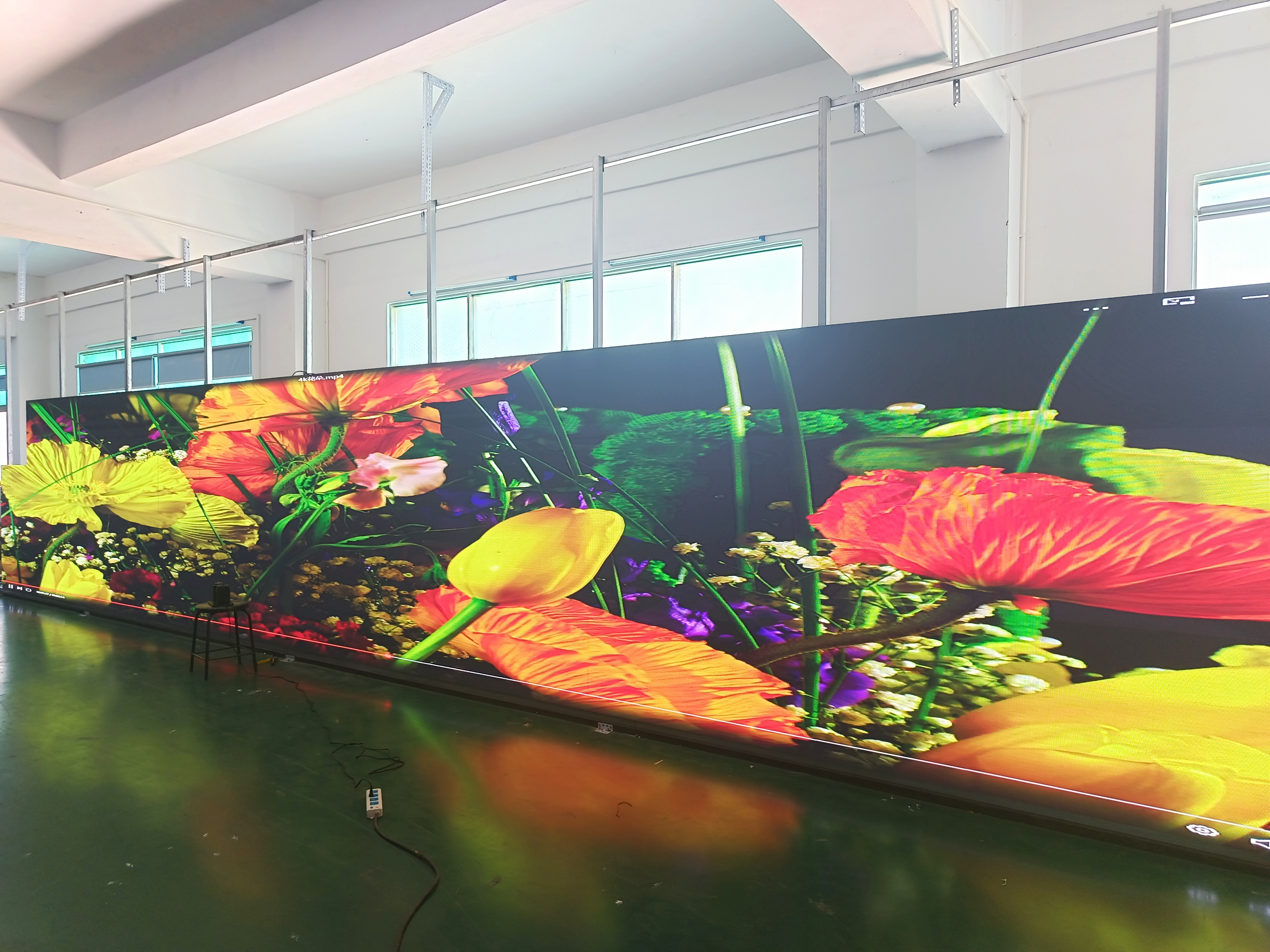

Factory & Production Lines

LED DISPLAY MANUFACTURER

Tentech has a large area of workshop for arranging productions, aging testing and quality control which about more than 1000m2.

9 Years+

Since 2015, LED Display Industry Experience

1000+M2

Production Lines, Aging Linesand QC Area

8

Countries Have Factory and Warehouses

LED MODULE PRODUCTION LINES

Tentech's LED display factory utilizes advanced automated machinery, including state-of-the-art Surface Mount Technology (SMT) equipment, allowing for precise and efficient placement of LED components onto circuit boards, ultimately guaranteeing the quality and consistency of every produced LED display.

Key Points of Tentech:

Automated Production:

Tentech's factory relies heavily on automated equipment for high-quality and consistent production of LED displays.

SMT Technology:

The key piece of automated equipment mentioned is the Surface Mount Technology (SMT) machine, which precisely places LED components onto circuit boards.

Quality Assurance:

By using advanced SMT technology, Tentech ensures the reliability and consitency of each LED display produced.

LED SMT

The lamp bead surface requires solder paste application before patching onto the SMT machine. After placement, reinforce the connection during reflow soldering to ensure proper bonding and reliability.

PCB SMT

IC SMT requires first applying solder paste, followed by placing ICs, resistors, capacitors, power sockets, and signal sockets. Finally, components are reinforced through reflow soldering for strong electrical connections.

Module SMT

LED module SMT involves soldering surface-mount components (LEDs, resistors, capacitors) onto a PCB using pick-and-place machines, followed by reflow soldering to ensure proper electrical connections and functionality.

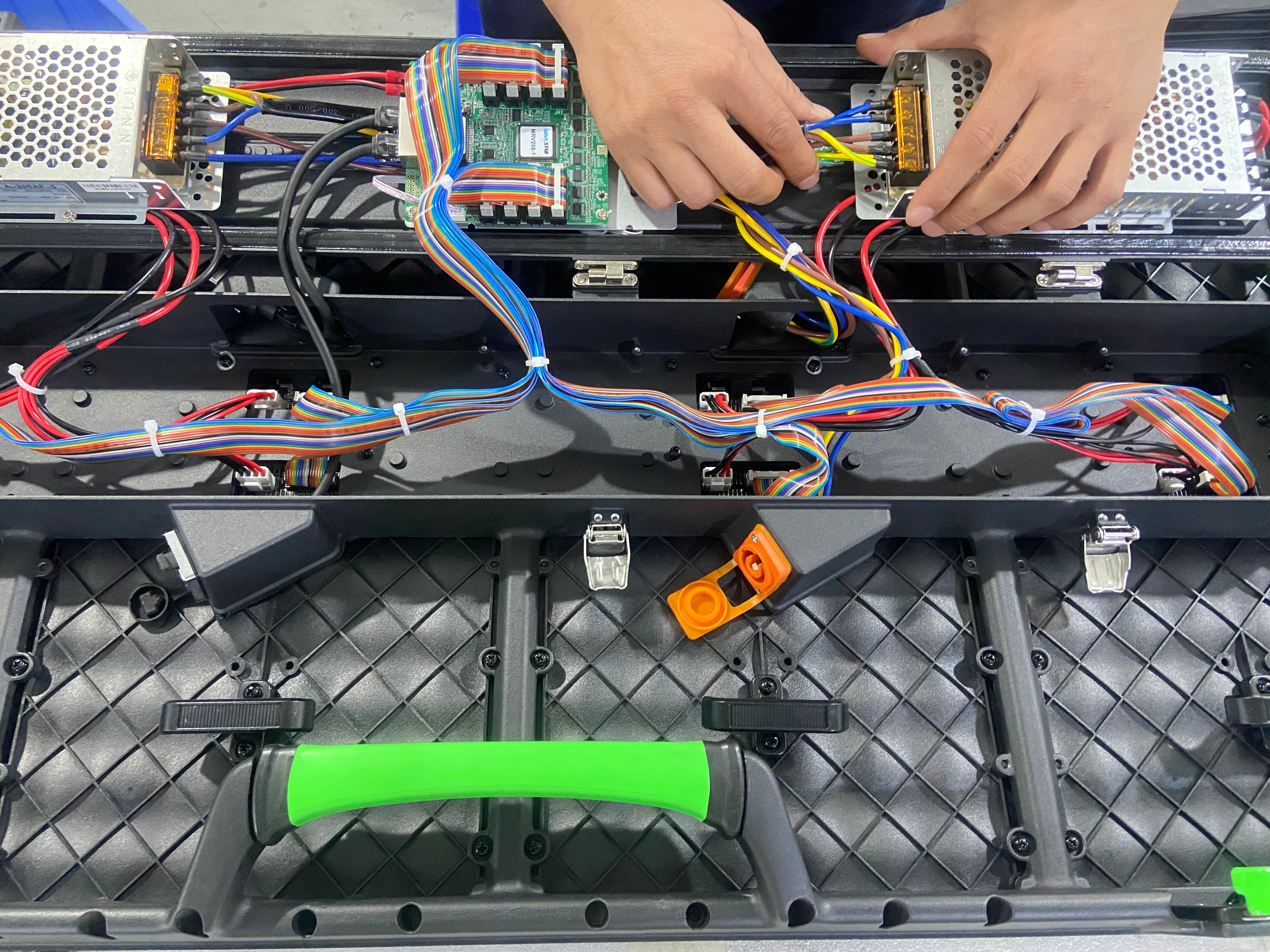

ASSEMBLY AND AGING LINES

led Display assemble

Professional workers are assembling LED Module, Power Supply, Receiving Card on LED Display cabinet.

Quality Control Lines

Quality controling is the most importing part before export. Experienced workers are QC checking.

LED SCreen aging

After finishing assebled the cabinets are subjected to an aging testing for 48/72 hours.

Factory's Photo Gallery